Introducing the CS-108 from Convergence Systems Limited

The CS-108 is a Bluetooth UHF RFID and Barcode Scanning Sled.

The CS-108 is a Bluetooth UHF RFID and Barcode Scanning Sled.

The official specifications can be found here. The following introductory video will give you a quick overview.

Practical Location Tracking

The CS-108 is a Bluetooth UHF RFID and Barcode Scanning Sled.

The CS-108 is a Bluetooth UHF RFID and Barcode Scanning Sled.

The official specifications can be found here. The following introductory video will give you a quick overview.

The Last Touch Asset Management is an application for managing hard to mark and/or dispersed assets. A simple smart phone app allows the user to quickly record the asset & location.

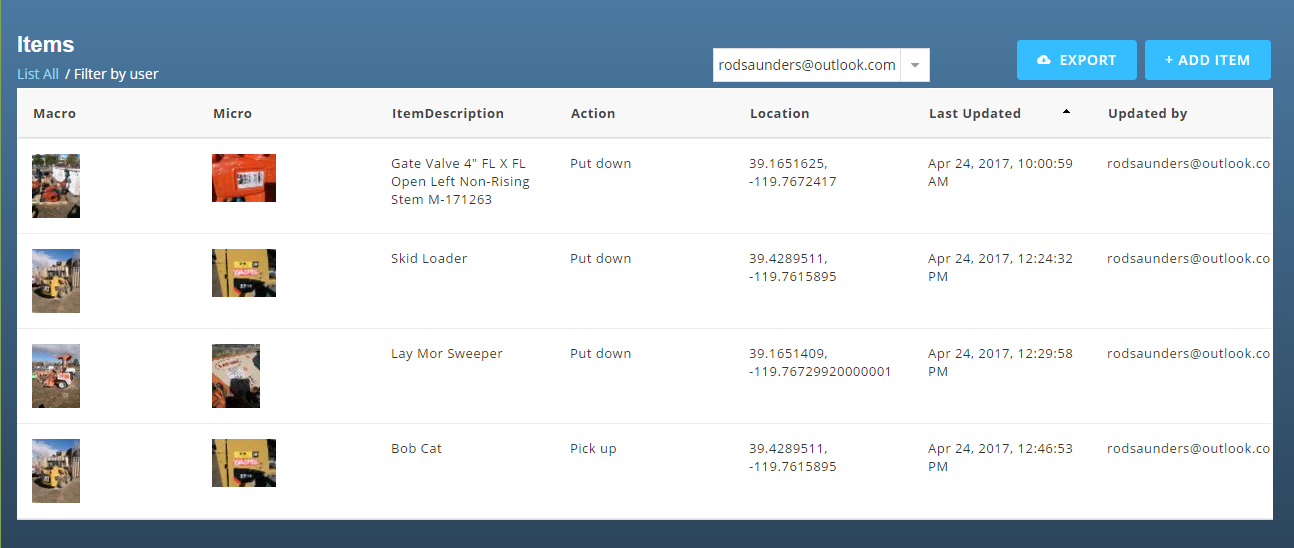

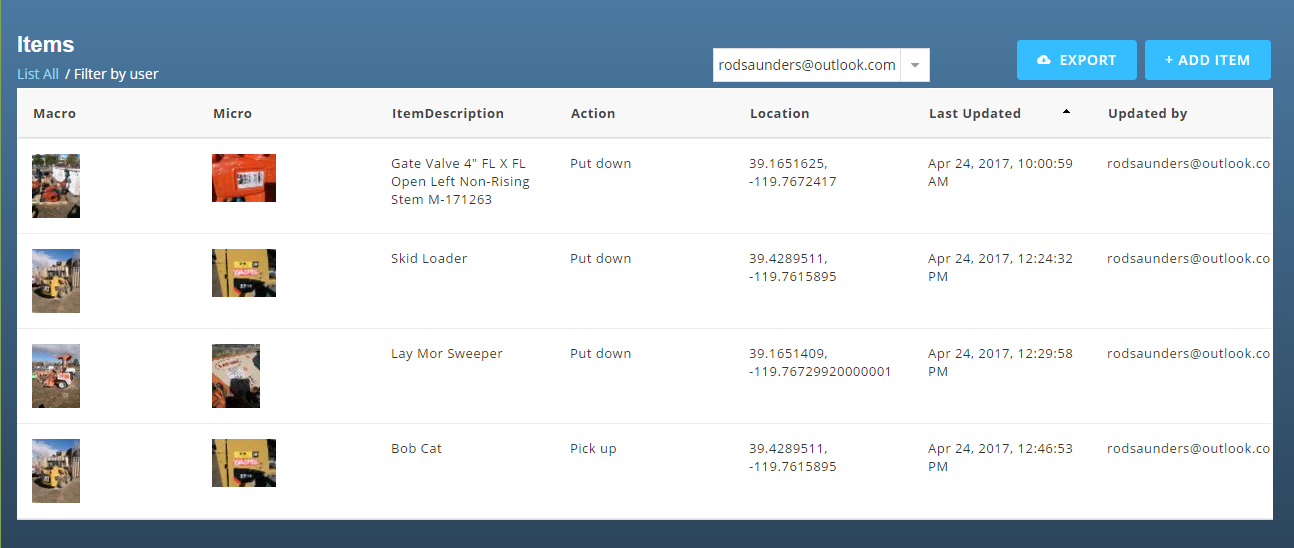

The Last Touch Asset Management Portal provides administration of the users and tools for managing the assets.

Items can be sorted by Description, Location, Time and User, as well as, filtered by User.

By comparing the Actions taken, Items both ‘PutDown’ and ‘PickedUp’ can be archived, removing them from the database. An Item Record Administers tool will be the first addition to the portal.

Item Records can be exported for import into external systems.

An Item Record Mapping tool will be the second addition to the portal.

This is a commercial enterprise platform, each tenant is sold in 5Gb increments. (that’s a lot of records) Modifications can be made for additional input fields, the actions list and number of pictures. At this time I have no plans for a horizontal subscription version. If you have questions please send me a message and I will email or call you promptly.

The solution is built on Google’s Cloud Platform and maintained by Appivo Ab. Insuring your data is secure, backed up and available.

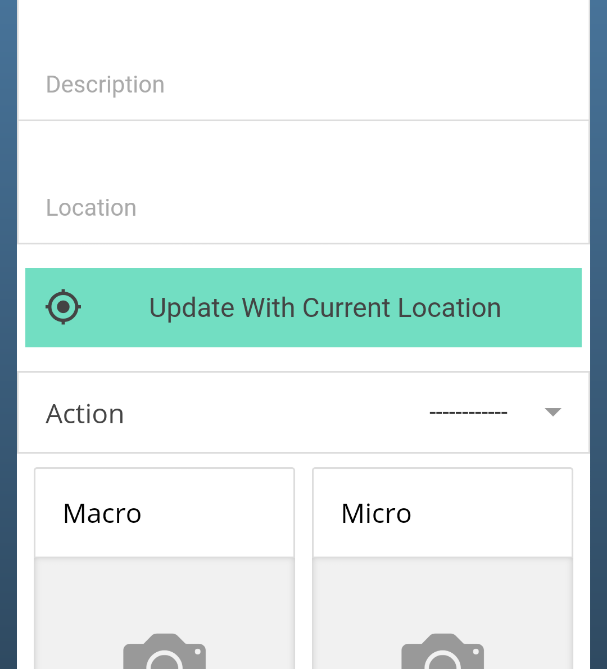

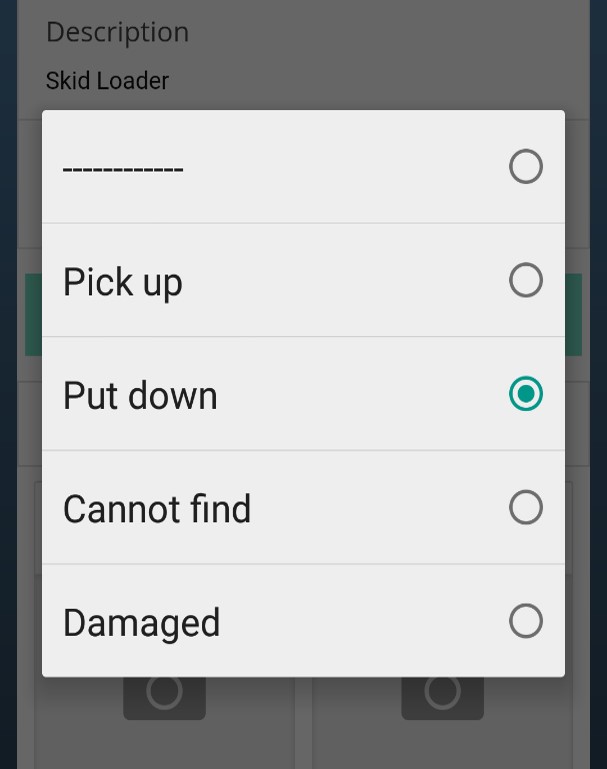

The Last Touch Asset Management is an application for managing hard to mark and/or dispersed assets. A simple application for both Android and iPhone allows the user to quickly record the asset & location of a ‘putdown’ or a ‘pickup’.

A ‘macro’ pic showing the general surroundings or full item and a ‘micro’ pic showing a unique identifier are the pictures worth a thousand words.

Adding a Description, GPS and choosing a Status completes the Item Record. The GPS is added to the record

User and Time data are added to the Item Record automatically.

The Last Touch Asset Management Portal allows the inventory to be managed and define Users.

For many years I have been ask for location solutions for Laydown Yards, Constructions Sites, Equipment Auctions, Parks Departments, so on and so on … Finally, there is a solution.

If you would like to be a beta customer click here. The formal launch is June 1st, 2017.

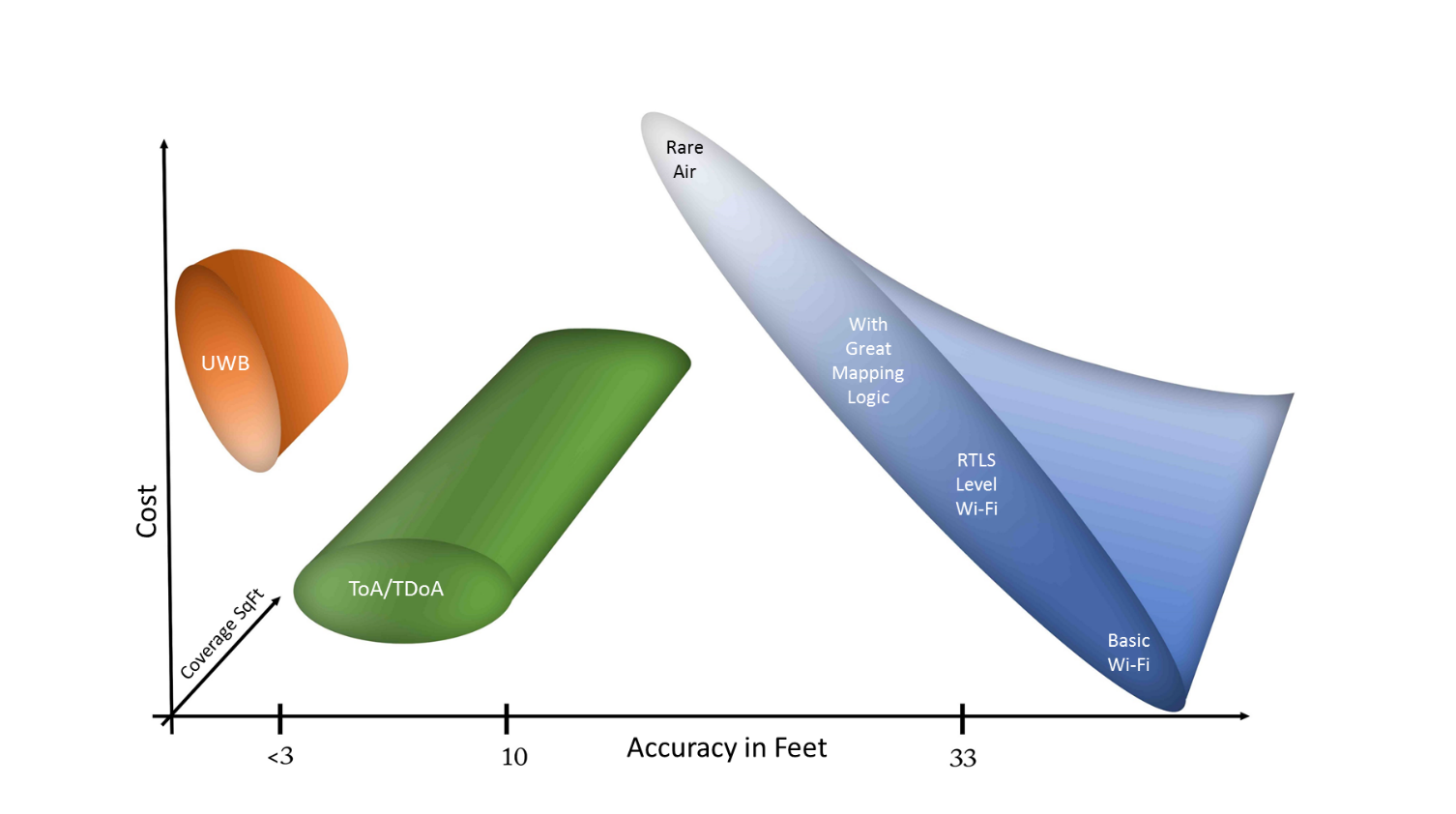

UWB is offered from multiple

companies and is maturing

nicely. It works best for welldefined

clear spaces with

high value propositions.

Pros:

Cons:

ToA is the sweet spot in Real

Time Location. It is best used

inside the four walls and

large open spaces.

Pros:

Cons:

Tracking with a Real Time Location System in a facility like this is no longer a difficult task. 1-2M accuracy can easily be obtained on a short ROI period. Primarily this is because everything is contained in the 4-walls.

A very simple application in an environment such as this is to recognize when all the parts, tool chests and fixtures are assembled in the work area so a work team can be scheduled, thus saving hours or even days.

Another is to simply locate tools or fixtures. It is always odd to me that items so large that they are moved by overhead crane get misplaced, but apparently they do.

Systems like this are scalable to mid-size production facilities as well; 50x100M seems to be a common size for everything from trusses to granite slabs to roll stock of various material and ROI well.

One of the challenges of RTLS applications for mid-size businesses has been interfacing outdoor inventory to indoor WIP.

Typically, inventory is barcoded today when it arrives. Most of the time, adding RFID tags is cost or environmentally prohibitive. Adding RTLS tags to be recaptured has been resisted by clients.

There is now one unique solution to bridge this gap. That is to add the Scanning Gun to the things being tracked in the RTLS system. A unique (to my knowledge) scan gun with integrated RTLS tag allows this to be accomplished.

The CSL 101 is not a sexy beast, but it gets the job done and has been field proven in many applications around the world. CSL also assures me the next generation is right around the corner.

Do you ever remove things from a trailer and put them in the ‘yard’ prior to putting them into a real system location?

Do you ever need that material before it is in the system?

You can now stop searching and know exactly where it was last seen. This also keeps it from being ‘lost’ to the system improving accuracy and lot tracking.

There is a lot to unpack here, but hopefully you can envision how this might help your business. Just reach out for further thoughts. www.rtlslab.com